Change from experience management to scientific management

Change from experience management to scientific management

Realize the accumulation of enterprise process assets and the effective landing of standard system

Realize the accumulation of enterprise process assets and the effective landing of standard system

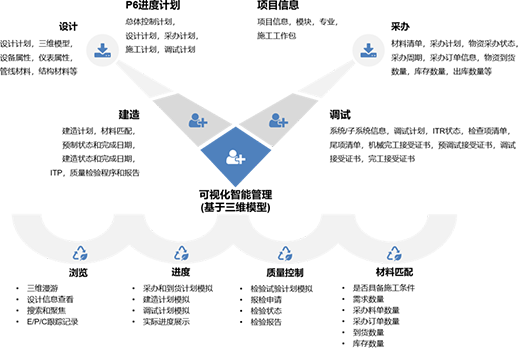

Improve the interoperability of data and support the project lifecycle management model

Improve the interoperability of data and support the project lifecycle management model

Products

: Data Warehousing

Products

: Data Warehousing

Services

: Handover standard establishment, Application planning, Procedure construction, Data technology services

Services

: Handover standard establishment, Application planning, Procedure construction, Data technology services

The engineering model and data management platform XSP can handle much larger models than using Web GL technology

The engineering model and data management platform XSP can handle much larger models than using Web GL technology

Pixel web streaming provides greater assurance of data security than Web GL technology

Pixel web streaming provides greater assurance of data security than Web GL technology

Be one of the few companies in China which have visual intelligent technology in project stages of design, construction, handover and operation; Participate in the implementation of CNOOC Offshore Oil Platform Digital Handover Project (EDIS)

Be one of the few companies in China which have visual intelligent technology in project stages of design, construction, handover and operation; Participate in the implementation of CNOOC Offshore Oil Platform Digital Handover Project (EDIS)

Rich experience in establishing handover standards, providing handover platforms, dividing work interfaces and implementing digital handover

Rich experience in establishing handover standards, providing handover platforms, dividing work interfaces and implementing digital handover